CLEANS YOUR PART AS GOOD AS NEW!

Rockingham Aqua Blast provide a comprehensive range of vapour blasting services for a wide range of mechanical parts and components in motorcycles, cars, watercraft and various general machinery. From our Perth, WA purpose built vapour blasting workshop we service locally and nationally with the highest of standards and precise attention to detail. We take pride in returning your Aluminium, Titanium, Bronze and Brass parts in mint condition through our vapour blasting process.

With over 30 years experience in reconditioning and restoring parts to their former glory, Rockingham Aqua Blast know how to exceed your expectations . Our Perth based vapour blasting service will remove any old paint, rust, scale, carbon or oxidization deposits from metal and plastic leaving your part as new. Rockingham Aqua Blast takes parts of all sizes and gets them back to you after a 2-3 day turnaround time in our workshop.

Advantages of Rockingham Aqua Blasting

Cleans By Flow of Water

As the name suggests, aqua blasting cleans by mixing an abrasive media with water and air at high pressures. The water cushions the impact protecting your parts from the erosion and distortion that dry blasting causes. Aqua Blasting produces an even and soft finish.

Eliminates Media Impingement

Dry blasting runs the risk of damaging parts and removing precious material thickness through high force impacts. In vapour blasting the water acts as a barrier between the abrasive media and your part, evening out the impact and resulting in a finish that can be smoother than factory.

Cleans Hard to Reach Areas

Traditional methods can only clean where the abrasive media can impact. Because aqua blasting uses flowing water, it can clean every nook and cranny of your part, even the bits you can’t see.

No Heat Generated and No Need For Nasty Chemicals

Vapour blasting eliminates heat damage. Water means less friction and less friction means less heat. Aqua blasting non-destructively cleans without the need for toxic chemicals.

Clean, Restore and Protect

Aqua blasting removes years of corrosion, grime and tarnish from the tightest places in record time. No other process compares with Aqua blasting for cleaning and finishing surfaces. With one step you can restore your part and keep it cleaner for longer.

No Risk of Damage Like Dry Blasting

Dry blasting risks damaging your parts through heat, friction, dust and sheer force. Why take the risk when aqua blasting is a proven more efficient and gentler method for cleaning and restoring surfaces.

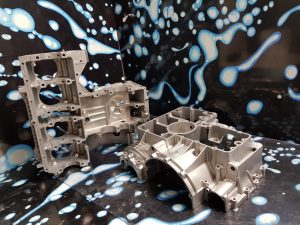

Our Vapour Blasting Services

At Rockingham Aqua Blast we operate a Vixen Aqua Blast 1515 out of our purpose built workshop to cater to all your Perth vapour blasting needs. The Vixen Aqua Blast 1515 is the top of the range and can vapour blast parts with dimensions up to 1.4m x 1.4m. We take parts locally and nationally, from nuts and bolts up we remove old paint, rust, scale and other deposits from your parts resulting in resurfaced parts that look better for longer with smoother, shinier surfaces. Our trained technicians specialise in the non-destructive reconditioning of engine parts for all types of vehicles and our vapour blasting process is ideal for cleaning and surface preparation of your parts. For expert vapour blasting done with precision and care contact Rockingham Aqua Blast today.

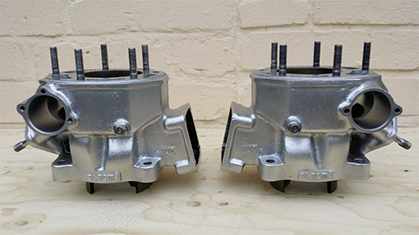

Motorcycles

Aqua blasting is ideal for the restoration and reconditioning for anything on two wheels.

Cars

Rockingham Aqua Blast provide exceptional service in degreasing and resurfacing your car parts for reconditioning or maintenance.

Jet Skis

We get into hard to reach areas to help protect your jet ski parts from corrosion and rust.

Other Vehicles

We deal with all things metal. If you need something aqua blasted on your 2, 3,4 or no wheeled vehicle or any mechanical parts Rockingham Aqua Blast have you covered.

Misc Mechanical Parts

Rockingham Aqua Blast can clean almost anything. If we can fit it into the aqua blasting workspace, we can clean it. Call us to find out if we can help you.

About Us

Who We Are

At Rockingham Aqua Blast we are proud of the work we do. Originally meeting in the U.K., Iain and Jonny of Rockingham Aqua Blast shared a mutual passion for restoring old cars and motorcycles. After years of being disappointed by the results of other companies the two old friends decided to purchase their own vapour blasting machine to get the quality they expected. Their skills and knowledge have grown, and they now have over 30 years of experience in restoring old parts back to pristine glory.

What We Use

In our speciality vapour blasting service we trust only the best machinery to get the job done. Our workshop uses a Vixen 1515 to get the best results for your part. The Vixen 1515 is the biggest and best in vapour blasting machinery and provides a superior finish. We take the utmost care to ensure that your part is taken care of from the moment we receive it to the reveal of your newly restored part. Every aspect of our work is the highest quality to ensure our service to you is the best it can be.

What We Value

At Rockingham Aqua Blast we are proud of the work we do. With years of experience aqua blasting our own parts we know what to look for and delight in providing first-rate Perth vapour blasting services. As two passionate restorers of old vehicles we know what exceptional quality looks like and strive to deliver excellency in every part we vapour blast. We value providing superior vapour blasting services to Perth and Australia with a dedication to integrity, customer service and prompt turnarounds.

OUR PROCESS

Parts will be photographed and inspected; any potential issues will be discussed with you

Certain parts or pieces may be taped off or plugged up

Parts are then vapour blasted then rinsed with clean water and dried with compressed air

Finished parts are then photographed before being available for pick up, or packaged up and shipped back to you

FREQUENTLY ASKED QUESTIONS

What types of metal can be Vapour Blasted?

At Rockingham Aqua Blast we specialise in restoring Aluminium, Titanium, Copper, Bronze, Brass and stainless steel. You might be surprised what can be vapour blasted, including some plastics. If you’ve got something you aren’t sure about, give us a call.

What is your Turnaround?

Once we have received the part, our standard turnaround is 2-3 working days in the shop. However, if you need a part express, contact us directly and we will do our best to sort something out.

Are Aqua Blasting, Vapour Blasting and Water Blasting the same thing?

Yes, all these terms refer to mixing an abrasive medium with water as opposed to a dry blast. The different terms all mean the same thing.

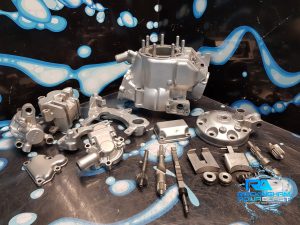

How do I prepare my parts for Vapour blasting?

Disassemble the parts and remove any brackets, bolts or bearings that you can. Threaded steel inserts, iron cylinder liners, valve seats cannot be removed so we will mask them off before blasting. It’s best to give the parts a preliminary clean before sending them to us. We are happy to do it, but it will increase the turn-around time and your expense. Gaskets and heavy sealants must be removed prior to blasting- the blaster will not remove them.

What can go wrong?

Most parts look fantastic and are ready to go once we give it a final inspection and touch up. Sometimes aqua blasting might reveal hidden cracks or cosmetic damage under the debris. Aqua blasting will make these much easier to see but will not repair them.

What is the process?

Typically, once we have received your part(s) we will inspect and photograph them, making sure to discuss any potential issues with you. After inspection we clean the part and plug it up if required. The part is now ready to be aqua blasted. From there we rinse and dry the part, doing our utmost to get all aqua blasting media rinsed off. Finally, we take photos of your beautifully restored part and get it ready for shipping back to you.

It is important to note that while we take the utmost care to remove any traces of blast media it is your responsibility to ensure the parts are spotless before reassembly. RINSE, RINSE, WASH, AND RINSE AGAIN

What’s the deal with return shipping?

Once we’ve finished restoring your part, we’ll ship it back to you as soon as we can. To make sure nothing goes wrong, the part will be shipped with insurance and tracking. The cost will depend on the size and weight of the part.

TESTIMONIALS

I sent the exhaust headers from my Ducati over to the guys from Rockingham Aqua Blast to be restored. The work was completed quickly, efficiently, and with fantastic service. The part looks amazing and I’m extremely happy with the work, thanks guys!

- Steve

RockinghamContact us for free advice and quotes

- Address: 5 Cort Way, Rockingham, WA, 6168

- Phone: 08 9500 1835

- Email: info@rockinghamaquablast.com.au

SOCIAL